- Drum Plant Machineries for 10L - 100kgs Drums

- Home

- Product Details

- Drum Plant Machineries for 10L - 100kgs Drums

- Home

- Product Details

- Downloads

- Drum Plant Machineries for 10L - 100kgs Drums

- Drum Plant Machineries for 10L - 100kgs Drums

- Introducing our comprehensive range of Drum Plant Machineries tailored specifically for the production of 10L - 100kgs drums, designed to cater to the diverse needs of industries worldwide. Engineered with precision and innovation, our machinery offers a versatile solution for manufacturing drums of varying specifications, meeting the stringent quality standards demanded by modern industrial applications. With a focus on efficiency and flexibility, our Drum Plant Machineries are equipped to handle diverse production requirements, ensuring optimal performance and reliability. Whether you're in the chemical, petroleum, or food and beverage sector, our solutions empower you to streamline production processes and meet evolving market demands with ease. Experience the pinnacle of drum manufacturing excellence with our range of Drum Plant Machineries, your trusted partner for unparalleled quality and performance.

- Machinery in Line as per Production Flow

- A 4-foot Guillotine Shearing machine, power-operated with a 3 H.P. electrical shearing under crank drive, geared and having a maximum cutting capacity of 1mm thickness sheet. The machine has a mechanical sheet clamper, front and back gauges, and a four edged cutting blade set duly hardened and ground complete.

- A 24-inch width body bending machine, power operated with a 2 H.P. electrical motor, Pedestal model, and M.S. Fabricated with gear drive. The machine is fitted with a feeding gauge and a shell knock-out system. All shafts are housed in bush bearings and have individual settings, complete with standard accessories.

- Drum body expander machine, hydraulically operated with a 7.5 H.P. power pack and hydraulic accessories. The machine has 2/4/16 segments expanded through a taper cone/taper nut system for conical expanding & normal drum expander system connected to the hydraulic cylinder through a bush system and retracted through an internal spring system. Segments are duly hard-chromed, segment assembly fitted on a sturdy M.S. fabricated stand. The machine is vertical, and the drum shell is to be fed manually into the machine. The machine is operated via a panel control system, electrical, and hydraulic accessories, complete with standard fittings and accessories.

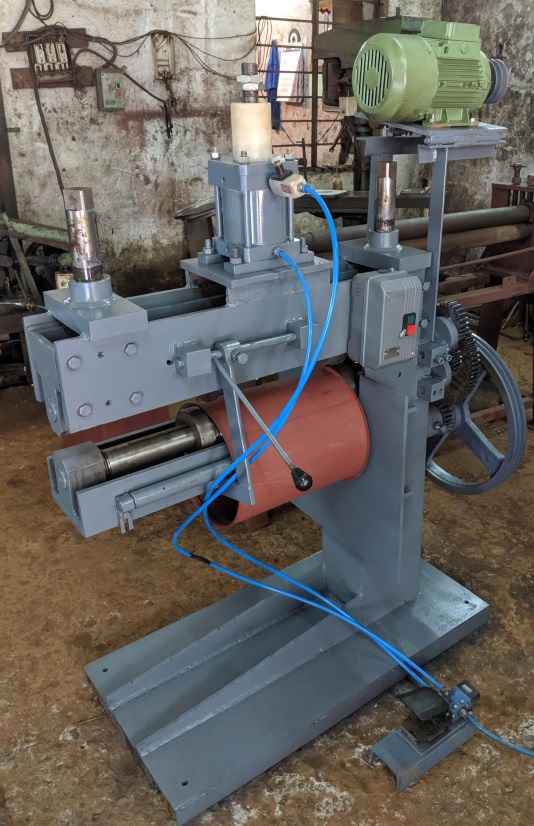

- Double-ended heavy duty Multiple corrugation machine, power operated with 3 H.P. electrical. Machine M.S. Fabricated and geared-driven with one set of dies duly hardened. Machine fitted with a gauge plate and guide rolls. Machine pneumatically operated via F.R.L. Unit, foot valve, and pneumatic accessories complete with standard fittings. Maximum and minimum height of drum from 10” to 20”.

- Double-ended horizontal heavy-duty flanging cum stackable machine, power-operated with 3 H.P. electrical. Machine M.S. Fabricated and geared-driven with one set of dies duly hardened. Two arms, which are pneumatically operated, complete the flanging and stackable operation. Machine pneumatically operated via a panel control system and pneumatic accessories complete with standard fittings. Maximum and minimum height of drum from 10” to 25”.

- Double-ended heavy duty flanging cum stackable machine, power operated with 3 H.P. electrical. Machine M.S. Fabricated and geared-driven with one set of dies duly hardened. Machine fitted with a gauge plate and guide rolls. Machine pneumatically operated via F.R.L. Unit, foot valve, and pneumatic accessories complete with standard fittings. Maximum and minimum height of drum from 10” to 20”.

- Semi-automatic, horizontal, double-ended drum seaming machine, power operated with 5 H.P. electrical. Machine M.S. Fabricated, pneumatically operated with ONE pneumatic cylinder provided for moving the right head. The head fits on the drum for the seaming process to begin and is released after the seaming process is completed with the four hands (first & second operation hands) fitted with CAM system. The machine is suitable for seaming drums from 10" diameter to a maximum of 25" diameter in a maximum 20-gauge thickness sheet. Machine fitted with two seaming chucks and two sets of seaming rollers duly hardened, pneumatic accessories, and complete with standard accessories.

- Semi-automatic, vertical, single-ended drum seaming machine, power operated with 3 H.P. electrical. Machine M.S. Fabricated and pneumatically operated, suitable for seaming drums from 10" diameter to a maximum of 15" diameter in a maximum 20-gauge thickness sheet. The machine features a table working on dovetails and screw assembly for height adjustments from 11" to a maximum of 26". Machine fitted with one seaming chuck and one set of seaming rollers duly hardened, pneumatic accessories, and complete with standard accessories.

- 270mm cutting and embossing die set for 20-liter drums, in pillar die set. Comprising of top cutting ring, buffer pressure plate, pressure ring, cutting ring, and forming block with spring assembly complete.

- WPS NON-SEGMENTED. (Die to make Top & Bottom Lids from sheet, this die will be fitted on the 80-Ton press).

- 280mm cutting and embossing die set for 20-liter drums, in pillar die set. Comprising of top cutting ring, buffer pressure plate, pressure ring, cutting ring, and forming block with spring assembly complete.

- WPS NON-SEGMENTED. (Die to make Top & Bottom Lids from sheet, this die will be fitted on the 80-Ton press).

- 270mm cutting and embossing die set for 20-liter drums, in pillar die set. Comprising of top cutting ring, buffer pressure plate, pressure ring, cutting ring, and forming block with spring assembly complete.

- WPS NON-SEGMENTED. (Die to make Top & Bottom Lids from sheet, this die will be fitted on the 80-Ton press).

- 280mm cutting and embossing die set for 20-liter drums, in pillar die set. Comprising of top cutting ring, buffer pressure plate, pressure ring, cutting ring, and forming block with spring assembly complete.

- WPS NON-SEGMENTED. (Die to make Top & Bottom Lids from sheet, this die will be fitted on the 80-Ton press).

- 100mm mouth curling with pillar die set complete.

- WPS NON-SEGMENTED. (Dies to make 100mm mouth curling on lids from sheet, this die will be fitted on the 30-Ton press).

- 100mm mouth curling with pillar die set complete.

- WPS NON-SEGMENTED. (Dies to make 100mm mouth curling on lids from sheet, this die will be fitted on the 30-Ton press).

- 100mm mouth curling with pillar die set complete.

- WPS NON-SEGMENTED. (Dies to make 100mm mouth curling on lids from sheet, this die will be fitted on the 30-Ton press).

- 100mm inner plug die set with pillar die set complete.

- WPS NON-SEGMENTED. (Dies to make 100mm inner plug on lids from sheet, this die will be fitted on the 30-Ton press).

- 2” bung piercing and bung fitting die set with pillar die set, complete.

- WPS NON-SEGMENTED. (Dies to make 2” bung piercing and bung on lids from sheet, this die will be fitted on the 30-Ton press).

- M.S. Fabricated paint booth with a horizontal rotary spinner adjustable type with a 1 H.P. motor and starter and reduction gearbox drive. Machine having a 5 H.P. exhauster system and a water tray below the rotary spinner to collect waste paint. Auto ejector attached to the machine for ejection of drum after painting is complete. Painting done manually. No painting equipment included in the machine.